F1 MANIPULATOR.RU

2020–2023: From Constraints to Innovation

Starting in 2020, under conditions of blockade and isolation in Artsakh, I began working with limited resources. Despite technical difficulties and external pressures, the first prototypes of multifunctional robots were created. Those years’ experiments demonstrated that it is possible to design and build systems capable of performing multiple functions simultaneously for agricultural, security, or automation purposes.

2023: A New Beginning in Yerevan

In 2023, after relocating to Yerevan, I continued my work in a new environment. An upgraded prototype was developed here, which is currently in the testing phase and being prepared for industrial production.

New Factory: Production and Investment Opportunities

2026: New Factory Construction

In 2026, we plan to start building a new factory based on an automated production cycle. According to the preliminary plan, the factory will be capable of producing up to 1,200 multifunctional robots annually. Our goal is to move beyond the testing phase and ensure continuous, scalable production, making technological solutions accessible for various industries and markets.

Investment Proposal

The project is open to investment partnerships. We offer up to a 45% stake, which includes not only a share package but also active participation in the project, providing access to industrial resources, ready-made technological solutions, and opportunities for market expansion.

Why This Matters

This investment promises not only financial returns but also a genuine opportunity to contribute to the development of key sectors of the country’s economy.

Our factory aims to produce technological solutions that can increase efficiency by up to 100%, particularly in agriculture, manufacturing, and other critical industries.

The project’s value extends beyond robot production or job creation. It is a step toward technological independence, economic modernization, and unlocking the country’s potential.

We are building a system forged in challenging conditions but rooted in principles of progress, resilience, and collaboration.

Attached below are the prototypes of our robots and technological solutions.

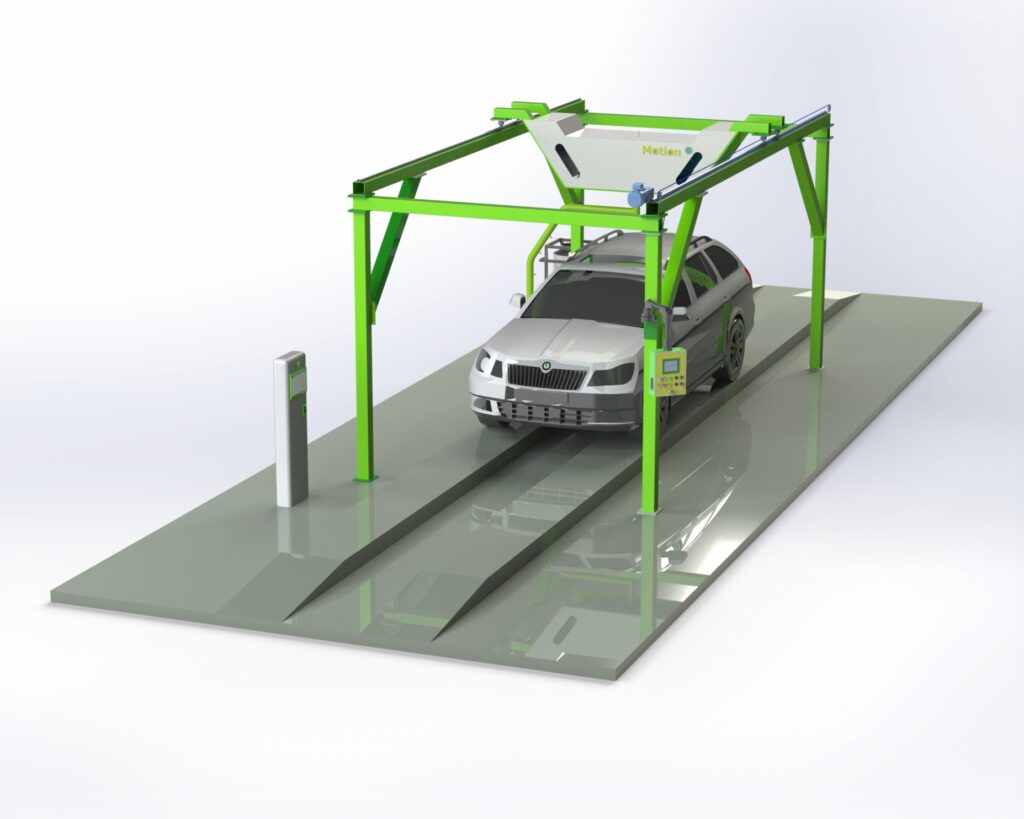

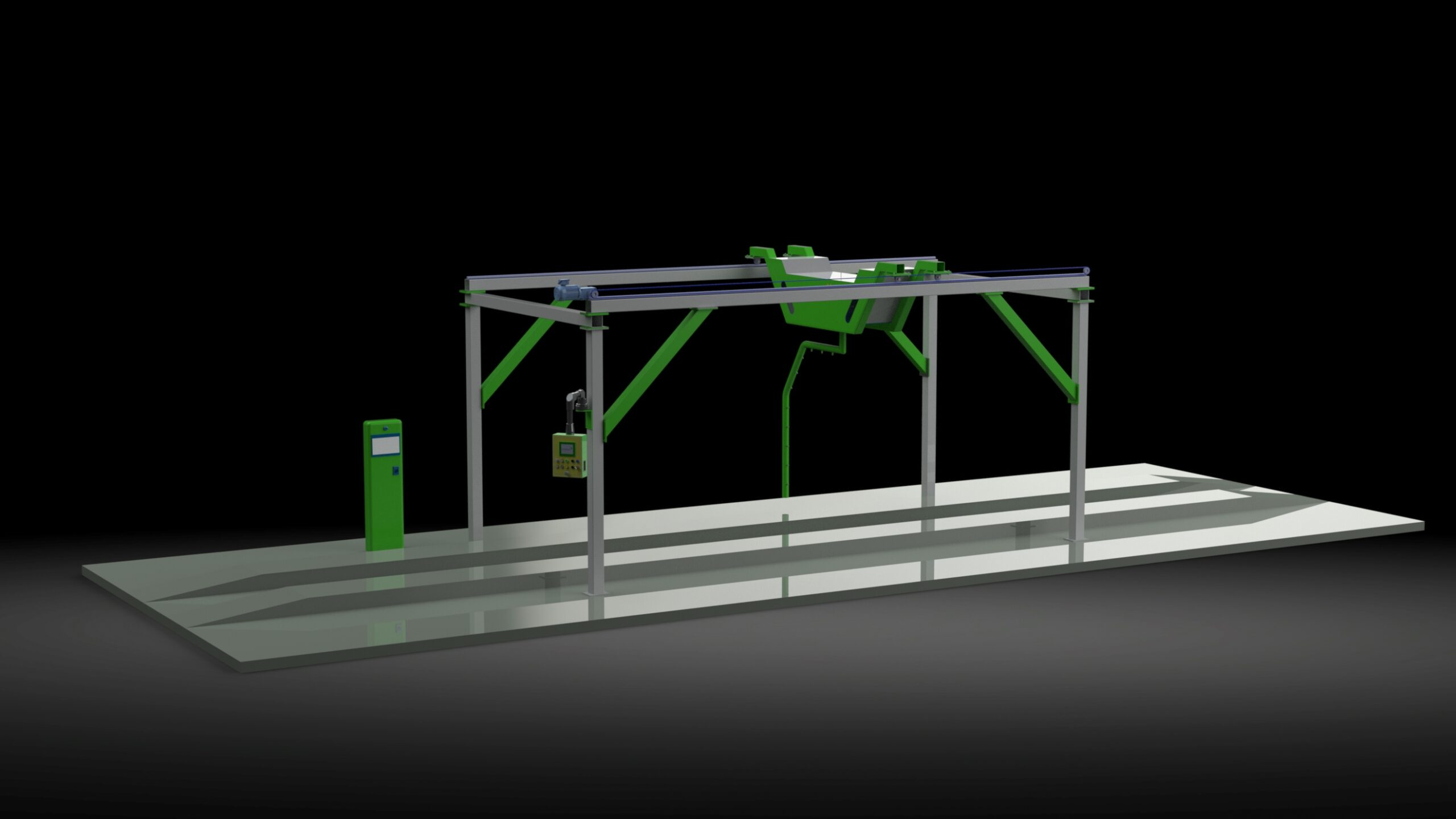

F1 ROBOT CAR WASH – Automated Car Wash Robot

Accessible Technology for Modern Businesses

We are developing advanced robotic systems aimed at transforming the service industry, making it more efficient, automated, and profitable. The F1 ROBOT CAR WASH is one of our flagship solutions, designed for automated, contactless car washing.

Project Vision

The F1 ROBOT CAR WASH is currently in the design phase, with plans to implement two commercial versions tailored to different business models:

- Integrated Solution for Existing Car Wash Stations

For businesses with established car wash facilities, the robot can be seamlessly integrated into existing infrastructure, reducing implementation costs. - Fully Automated Station Without Staff

A turnkey solution that can be installed in almost any location, providing consistent, high-quality car washing 24/7 without human intervention.

Advantages

- Smart Contamination Detection

The robot analyzes the vehicle’s surface contamination level and automatically manages the cleaning process. - Fast, Precise, and Profitable Operation

Minimal costs, reduced service time, and consistent quality for every wash. - Enhanced Business Visual Value

Clean and shiny vehicles boost customer trust and encourage repeat visits.

Target Deployment Locations

- Business centers

- Gas stations

- Parking lots

- Hotels, commercial, and residential complexes

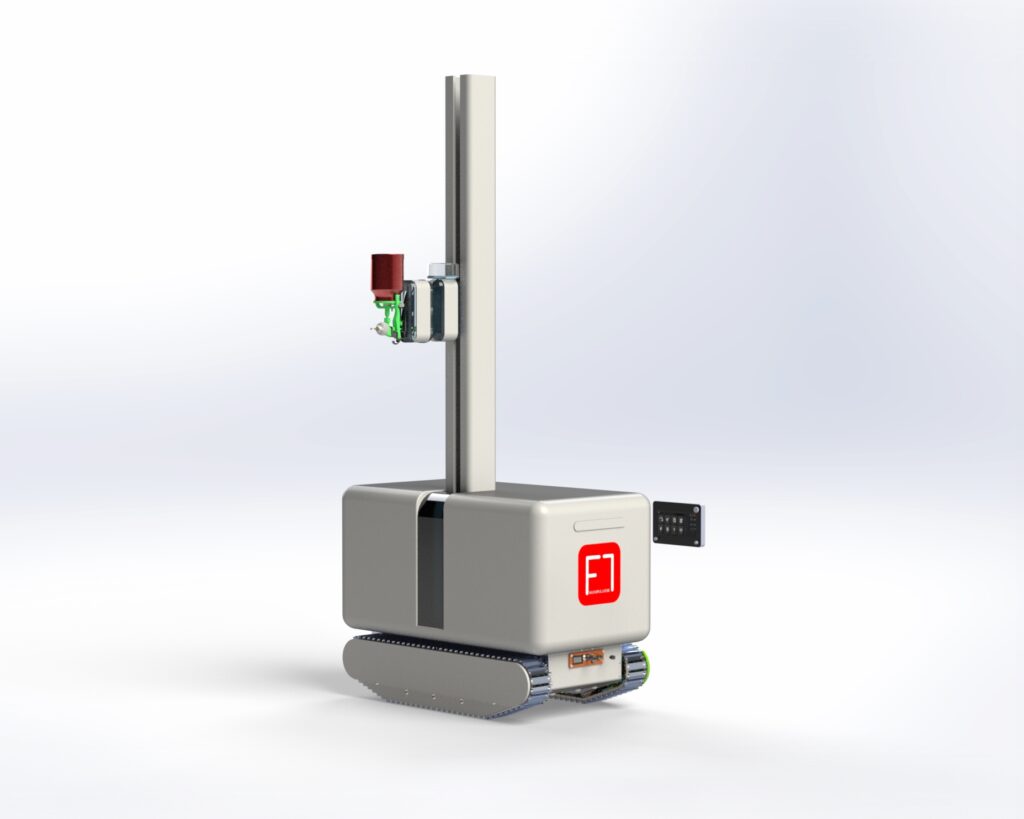

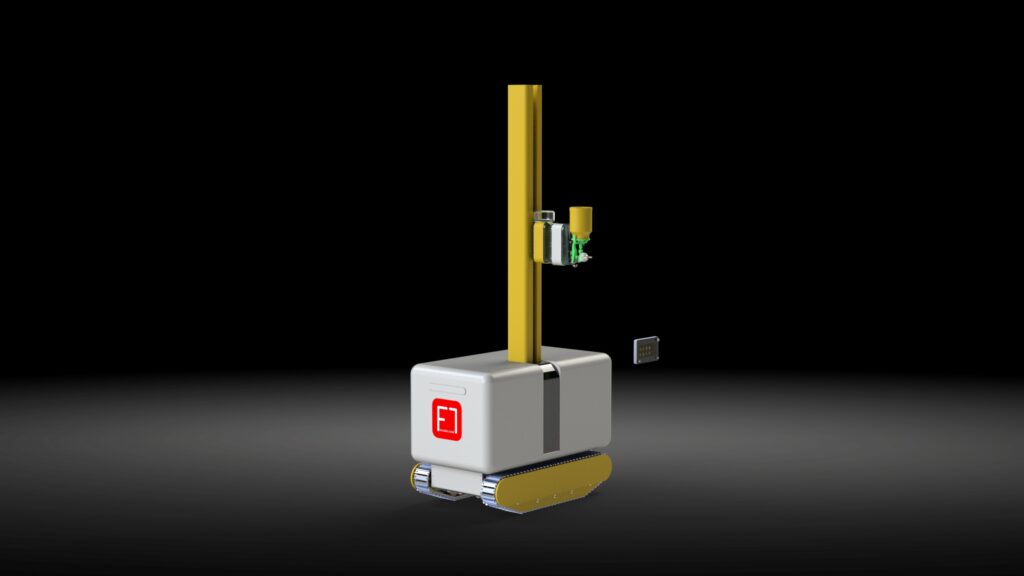

F1 MANIPULATOR – Multifunctional Assistant for Construction and Industry

Smart Robot for Automating Technical and Support Tasks

The F1 MANIPULATOR is being designed as a multifunctional robot for automating technical and support tasks in construction and industrial sectors. It is tailored to operate in diverse environments, enhancing work organization, supply chains, and technical process optimization.

Objective

To create a smart robot that automates time-consuming, resource-intensive, and attention-demanding processes. The robot can be remotely controlled or operate in pre-programmed modes, easily integrating into various infrastructures.

Advantages

- Technical Support and Process Optimization

Facilitates repetitive or precise tasks, improving workflow stability and organization. - Operation in Challenging Environments

Suitable for conditions where human involvement is limited or risky. - Easy Installation and Operation

Ready for quick integration without complex engineering preparation. - Flexibility and Customization for Various Tasks

Designed to be reprogrammable, adapting to specific business needs.

Benefits for Users

Time and Human Resource Savings

Reduces reliance on manual labor, cutting time and costs.

Clearer and More Organized Workflows

Streamlined operations for enhanced efficiency.

Supportive Robot for Efficient Task Execution

Enables effective preparation, maintenance, or other ongoing technical tasks.

F1 UNIVERSAL – Versatile Robot with Flexible Arm

The F1 UNIVERSAL is designed as a multifunctional robot for automating complex and diverse tasks, particularly in agriculture, logistics, and retail. It is engineered for high efficiency, with a focus on agricultural processes, aiming to boost productivity by up to 100%.

Objective

The robot is developed to automate agricultural tasks, ensuring efficiency, quality, and cost reduction. It can perform a range of functions, from loading to irrigation and other operations. The F1 UNIVERSAL is flexible and can quickly adapt to various working conditions.

Advantages

- Adaptability to Diverse Tasks

The robot is multifunctional, applicable across industries, from agriculture to logistics and retail. - Technological Flexibility

Operates effectively in challenging terrains and suboptimal conditions. - Automated Operations

A single robot performs multiple functions, such as supply, irrigation, loading, and more. - Quick Implementation

Easily integrates into existing infrastructures without complex technical preparation.

Benefits for Users

Automated Workflows

Improves workplace safety and transparency through automated operations.

Comprehensive Solutions

The robot can handle multiple tasks simultaneously, offering versatile applicability.

Increased Productivity

Enhances efficiency in agriculture by reducing the need for manual labor and accelerating processes.

F1 HI – Robot for Area Maintenance and Security

Description

The F1 HI is designed to provide fully automated solutions for area maintenance, security monitoring, fire suppression, and plant irrigation. Operating 24/7, the robot features remote control and monitoring systems, optimizing workflows in various sectors, particularly in large areas and challenging conditions.

Advantages

- Round-the-Clock Security Monitoring

The F1 HI ensures continuous security by monitoring areas in real time, reducing risks and potential issues. - Autonomous Irrigation and Fire Suppression Systems

The robot handles irrigation and fire suppression with minimal human involvement. - High Mobility in Field Conditions

Designed to operate in difficult and hard-to-reach terrains, ensuring broad applicability across diverse environments.

Benefits for Buyers

Automated Solutions for Area Maintenance

The F1 HI provides continuous maintenance, security monitoring, and fire suppression for large areas without human intervention, enhancing operational efficiency and reducing labor costs.

Ready-to-Use, Comprehensive System

The F1 HI is fully prepared for integration into existing systems without complex setup. It can be deployed and operated immediately, accelerating processes and delivering instant results.

Մենք պատրաստվում ենք կառուցել մեր Factory Construction Using Specialized Containers

The factory will utilize specialized containers, providing three key advantages:

- Rapid Construction: The use of containers will enable quick completion of the construction process.

- Mobility: Containers are easy to transport, allowing the factory to be relocated swiftly if needed.

- Lightweight Structure: Containers are lightweight yet durable, making them ideal for flexible production spaces.

These advantages will help us prepare the factory quickly and efficiently, adapt to changes, and ensure high flexibility in production processes.

F.CRM – Smart System for Everyone

We are ready to launch our proprietary CRM system, F.CRM, which will serve not only our team but also our partners and clients.

- AI-Powered System: Assists in managing business processes, tracking progress, and making optimal decisions.

- Universal Access: Partners and clients will have access to the system to monitor and track their orders, tasks, and the entire communication process.

- Transparent and Accessible: All parties can regularly check information and collaborate on the same platform.

F.CRM becomes the heart of our business, ensuring coordinated work, rapid responses, and professional management.

F1MANIPULATOR.RU – Our Official Platform

We have launched our official website, F1MANIPULATOR.RU, designed as a centralized platform for all our partners and clients.

Personal Account and Data Security

Each user will have a personal account for tracking orders, communicating with support, and accessing resources. Data is protected with modern standards.

Custom Order System

Users can place specialized orders on the platform, specifying technical requirements and business goals to receive tailored robotic solutions.

24/7 Technical Support

The website offers round-the-clock technical support, resolving issues, providing consultations, and assisting in complex situations.

Software Updates

Registered users and partners will receive automatic software updates for robots, ensuring system modernity and security.

Solutions for the Future

The platform will also serve as a hub for distributing new solutions, training materials, and innovative products, fostering an open and evolving ecosystem.

What the Investor Receives for a 45% Stake

4.9% Stake for Key Team Members

A total of 4.9% stake is planned to be allocated to key project employees (analysts, engineers, managers) as a reward for long-term commitment and contribution to results.

Project Stake – 45%

Upon investment, the investor will receive a 45% stake in the project, formalized through an investment agreement.

Fully Operational Factory – January 6, 2026

On January 6, 2026, the investor will gain access to a fully operational factory ready for industrial production, capable of manufacturing 120 to 1,200 robots annually.

Access to F.CRM System

The investor will receive access to the F.CRM management system to monitor ongoing project activities and maintain communication.

Security and Oversight Mechanisms

Full project management and strategic decision-making will remain under the control of the founding team to ensure security, confidentiality, and long-term stability.

My Goal and Rationale

I, Heros Poghosyan, present a high-tech production project aimed at establishing a robotics factory ready to develop and launch revolutionary products.

Why Invest Now

- Years of Experience:

From 2020 to 2025, six functional prototypes have been designed and built with limited resources, demonstrating our professional capabilities and commitment to sustainable development. - High Profit Potential:

Investing at this stage can multiply value significantly. Upon factory launch, the share value is expected to increase substantially due to unique technologies and market demand. - Production Flexibility:

The factory is designed with technological flexibility, enabling easy adaptation or expansion of production lines to respond to market changes.

Objective

To create not only a robotics factory but also an innovative platform that will stimulate local industry, technological independence, and economic modernization.

Robotics Startup Financial Analysis

We offer a 45% stake for $1.3 million (520 million AMD, exchange rate: 400 AMD = 1 USD). 80% of the investment (416 million AMD) will be directed to the company’s fund to support the construction of a container factory, development of AI and F.CRM systems, production of multifunctional robots, and international market expansion. The financial projections below are conservative and reflect the impact of the investment.

Investment Allocation

416 million AMD ($1,040,000) will be allocated as follows:

- 45% (187.2 million AMD) — Construction and equipment expansion for the container factory.

- 25% (104 million AMD) — AI and F.CRM system development (model development, servers).

- 20% (83.2 million AMD) — International marketing and sales promotion.

- 10% (41.6 million AMD) — Operational expenses (maintenance, technical support).

Key Financial Assumptions

- Robot sales: 120 units in the first year (1 robot/day, 10/month), 1200 units in the second year (10 robots/day, 100/month).

- AI and F.CRM expenses: Model development, servers, F1MANIPULATOR.RU website maintenance.

- Taxes: 20% on profits, accounting for initial losses.

- Marketing growth: Targeting business centers, gas stations, and industrial enterprises.

First Year (2026)

Startup Costs

| Description | Amount (AMD) | Amount (USD) |

|---|---|---|

| Container factory construction | 100,000,000 | 250,000 |

| Equipment and materials procurement | 50,000,000 | 125,000 |

| Production of first 200 robots (1,500,000 AMD/robot) | 300,000,000 | 750,000 |

| Total Startup Costs | 450,000,000 | 1,125,000 |

Annual Expenses

| Description | Amount (AMD) | Amount (USD) |

|---|---|---|

| Staff salaries | 40,000,000 | 100,000 |

| AI and F.CRM development | 25,000,000 | 62,500 |

| F1MANIPULATOR.RU maintenance and technical support | 10,000,000 | 25,000 |

| Production facility maintenance | 5,000,000 | 12,500 |

| Marketing and advertising | 35,000,000 | 87,500 |

| Reserve fund | 5,000,000 | 12,500 |

| Tax expenses (20%) | 0 | 0 |

| Social security and other expenses | 10,000,000 | 25,000 |

| Insurance | 5,000,000 | 12,500 |

| Maintenance and repairs | 7,000,000 | 17,500 |

| Transportation expenses | 5,000,000 | 12,500 |

| Quality control expenses | 3,000,000 | 7,500 |

| Management expenses | 10,000,000 | 25,000 |

| Office expenses | 3,000,000 | 7,500 |

| Total Annual Expenses | 158,000,000 | 395,000 |

Annual Revenues

| Description | Amount (AMD) | Amount (USD) |

|---|---|---|

| Robot and service sales (10 robots/month × 1,000,000 AMD × 12 months) | 120,000,000 | 300,000 |

| Total Revenues | 120,000,000 | 300,000 |

Results

First-year loss: -488,000,000 AMD (-$1,220,000), driven by significant investments in factory construction, AI/F.CRM development, and marketing. The investment (416 million AMD) will partially cover this loss and support the launch of production.

Second Year (2027)

Annual Expenses

| Description | Amount (AMD) | Amount (USD) |

|---|---|---|

| Staff salaries | 60,000,000 | 150,000 |

| AI and F.CRM development | 20,000,000 | 50,000 |

| F1MANIPULATOR.RU maintenance and technical support | 15,000,000 | 37,500 |

| Production facility maintenance | 10,000,000 | 25,000 |

| Marketing and advertising | 60,000,000 | 150,000 |

| Reserve fund | 10,000,000 | 25,000 |

| Tax expenses (20%) | 176,000,000 | 440,000 |

| Social security and other expenses | 15,000,000 | 37,500 |

| Insurance | 10,000,000 | 25,000 |

| Maintenance and repairs | 15,000,000 | 37,500 |

| Transportation expenses | 10,000,000 | 25,000 |

| Quality control expenses | 8,000,000 | 20,000 |

| Management expenses | 20,000,000 | 50,000 |

| Office expenses | 6,000,000 | 15,000 |

| Production expansion expenses | 50,000,000 | 125,000 |

| Total Annual Expenses | 485,000,000 | 1,212,500 |

Annual Revenues

| Description | Amount (AMD) | Amount (USD) |

|---|---|---|

| Robot and service sales (100 robots/month × 1,000,000 AMD × 12 months) | 1,200,000,000 | 3,000,000 |

| F.CRM subscriptions (100 subscribers × 100,000 AMD/month × 12 months) | 12,000,000 | 30,000 |

| Total Revenues | 1,212,000,000 | 3,030,000 |

Results

Second-year profit: 727,000,000 AMD ($1,817,500), of which the 45% stake represents 327,150,000 AMD ($817,875) for investors.

Two-Year Total Results

| Description | Amount (AMD) | Amount (USD) |

|---|---|---|

| Total Revenues | 1,332,000,000 | 3,330,000 |

| Total Expenses (including startup) | 1,093,000,000 | 2,732,500 |

| Total Net Profit | 239,000,000 | 597,500 |

| 45% Stake for Investors (Year 2) | 327,150,000 | 817,875 |

Why Invest

A $1.3 million investment will ensure the rapid launch of the factory and large-scale robot production. Investors will receive a 45% stake, yielding 327.15 million AMD ($817,875) in profit in the second year, with actual revenues potentially exceeding projections due to demand for robots (agriculture, industry, services) and F.CRM’s global expansion. 80% of the investment (416 million AMD) will be directed to company growth, including:

- Container factory construction and expansion for flexible and rapid production.

- AI and F.CRM development for intelligent robot functionality and business management.

- International marketing targeting business centers, gas stations, and industrial enterprises.

These projections are conservative, and the factory’s flexible design will allow quick adaptation to market demands, ensuring long-term profitability.